Border & Finishing Guide for Custom Patches

How edge styles and finishing details affect durability, appearance, and performance, explained simply.A patch without a proper border is just a piece of loose fabric waiting to fall apart. The border isn’t just a decoration; it is the structural seal that prevents the threads from unspooling and the backing from separating.

If you are outfitting a team for the oil fields or manufacturing uniform insignia for a JBSA squadron, you need to know the difference between a Merrowed Edge and a Laser Cut Edge. Choose the wrong one, and your patches will fray before the first wash.

Why Borders & Finishing Matter

Think of a patch border like the hem on a pair of jeans. If you cut the denim and don’t hem it, it unravels into a stringy mess.

Durability

The border locks the embroidery thread, the fabric base (twill), and the backing together into a single unit.

Aesthetics

A thick border makes the patch pop off the garment. A thin border makes it blend in.

Protection

In the humid San Antonio climate, moisture gets into exposed fabric edges. A sealed border keeps the moisture out and the patch flat.

The Main Patch Border Types

There are two industry standards you will see 99% of the time, plus a few specialty options.

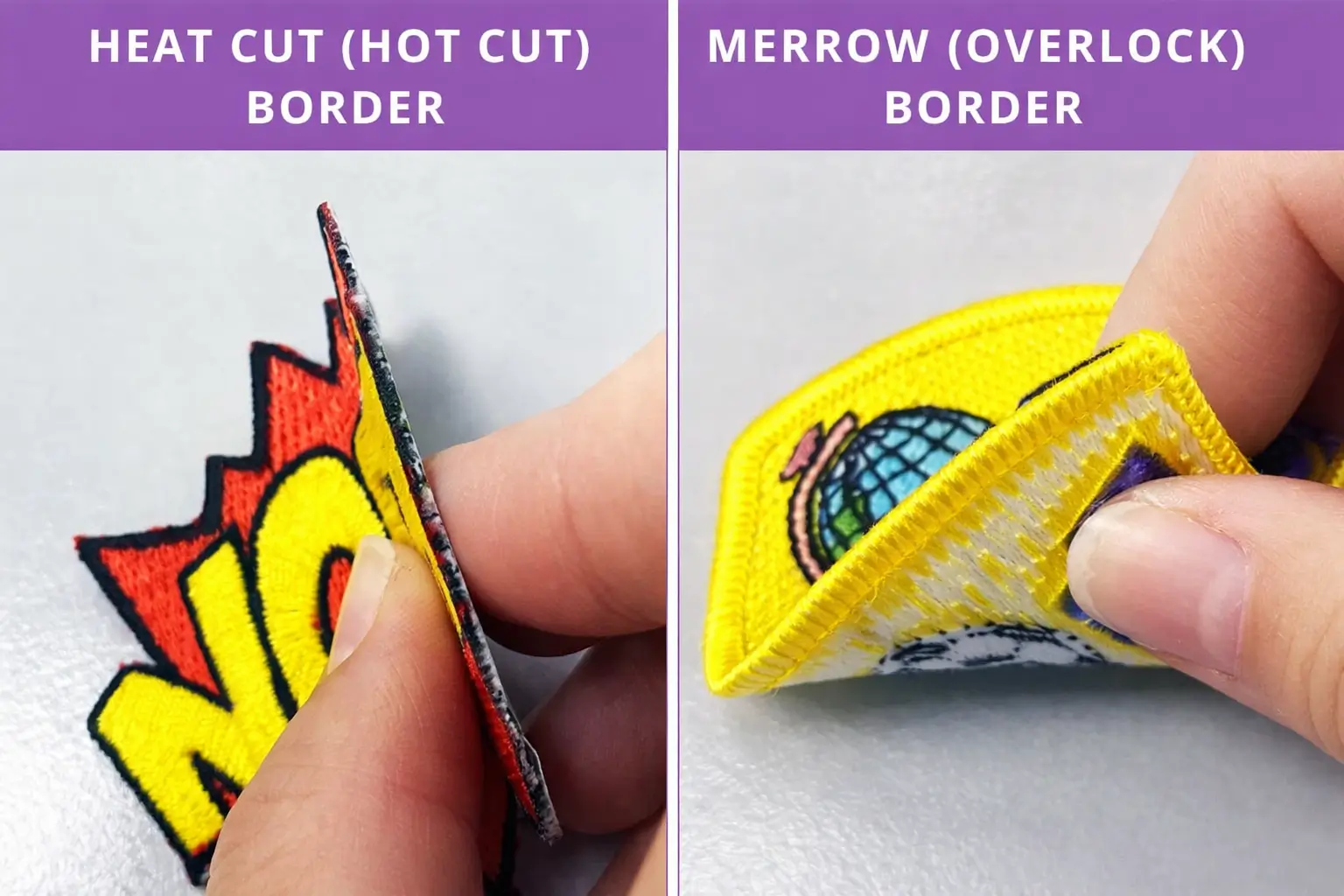

Merrowed Border

Classic Raised Edge

Laser Cut Edge

Heat-Sealed Precision

Stitched Border

Satin Stitch

No Border / Raw Edge

Cut MaterialPatch Finishing Options Explained

Beyond the visual border, we use finishing techniques to ensure longevity.

Heat-Sealed Edges

Even if you order a Merrowed border, we often run a hot knife or laser around the raw twill before applying the border. This ensures that no white threads poke through the darker border stitching later.

Overlocked Stitching

This is the technical term for Merrowing. It uses three separate threads looping together to create that dense, rope-like finish. It is the strongest mechanical bond in the textile industry.

Fray Protection & Edge Sealing

For Woven Patches, which are thinner, we often apply a light liquid fray-check or heat treatment to the back of the border to stiffen it up so it doesn’t curl in the dryer.

Choosing The Right Border

Don’t reinvent the wheel. Here is the standard pairing for each material.

| Patch Type | Recommendation | Why? |

|---|---|---|

| Embroidered Patches | Standard: Merrowed Custom: Laser Cut | Merrowed looks the most “finished” and traditional. Use Laser Cut only for complex custom shapes. |

| Woven Patches | Laser Cut | Woven patches are thin and flat. A heavy merrowed border can sometimes look too bulky on a delicate woven patch. |

| PVC / Rubber Patches | Sewing Channel | You can’t stitch through thick rubber with a merrow machine. Instead, we mold a small groove around the edge where the needle can stitch it to the garment. |

| Leather Patches | Laser Cut | To make it look traditional, we often etch a “faux stitch line” inside the border, but we rarely wrap thread around the raw edge of leather. |

| Chenille Patches | Merrowed | Chenille is built on a felt backing. You need a heavy merrowed border to physically hold the felt and the yarn together. |

| Printed Patches | Merrowed | Since printed patches are very flat, adding a Merrowed border frames the artwork like a picture, making it look higher quality. |

Border Styles by Patch Shape

Geometry dictates the machine we can use.

Circular & Oval

The machine spins the patch in a perfect circle. It’s fast, clean, and the industry standard.

Rectangular & Shield

The operator manually turns the patch at the corners. Perfect for police shields and name tapes.

Custom Die-Cut

If your design has “innies” (concave angles, like the space between star legs), a merrow machine breaks. You must use Laser Cut.

The “Inside Corner” Rule

Here is a quick test. Look at the outline of your logo. Does it have any sharp inside corners (like the letter “V”)? If yes, you cannot use a Merrowed border. The machine can only sew on outside curves.

Border Durability Comparison

It is a literal physical barrier. The overlocked thread wraps around the edge, protecting the raw fabric from ever touching the elements.

The heat seal is strong, but it is just melted polyester. Over time, heavy washing and friction can cause the very edge to “fuzz” slightly.

Common Border & Finishing Mistakes

We see these errors in artwork files every day. Avoid them to save time.

The “Impossible Turn”

The “Invisible” Border

The “Raw Edge” Gamble

How Borders & Finishing Affect Pricing

Does a fancy border cost more? Sometimes.

Laser Cut

For custom shapes, this is the default method. There is usually no extra charge because the laser cuts the patch out anyway.

Merrowed

Because this requires a human operator to physically run the patch through a second machine (the overlocker), it adds labor. However, for simple circles and squares, it is often included in the base price.

Complex Cuts

If your patch has internal cutouts (like a donut hole), the laser has to run longer, and “weeding” the excess material takes time.

Frequently Asked Questions About Patch Borders

Answers to common questions about edge finishing, thickness, and style.

DurabilityWhich border lasts the longest?

Which border lasts the longest?

Merrowed. It is a reinforced thread bumper. It survives industrial laundering better than any other finish.

ProductionCan I change the border after production?

Can I change the border after production?

No. The border is the final step. Once we cut the patch or sew the edge, it cannot be undone without destroying the patch.

ThicknessDoes border choice affect patch thickness?

Does border choice affect patch thickness?

Yes. A Merrowed border adds significant thickness to the edge (about 1/8th inch). A Laser Cut patch remains perfectly flat (paper thin) at the edge.

ComparisonIs laser cut better than merrowed?

Is laser cut better than merrowed?

Not “better,” just different. Laser Cut is for complex shapes; Merrowed is for simple shapes and durability.

CustomizationCan I combine border styles?

Can I combine border styles?

You can simulate it. We can use a Satin Stitch (embroidery) just inside the edge to look like a border, and then Laser Cut the outside. This gives you the look of a heavy border with the shape flexibility of a laser cut.