Custom Leather Patches San Antonio

Rugged & Laser-PrecisionPremium laser-engraved, debossed, and stitched leather patches. Built for hats, jackets, and the South Texas sun. Whether it’s for a cattle ranch in Bexar County or a corporate fleet of trucker hats, custom leather patches offer a texture and smell that screams quality.

Genuine Leather vs. Faux (Vegan) Leather

We get asked this daily: “Which one is better?” It depends on what you value more.

Genuine Leather

This is natural cowhide. It smells like leather. It feels organic.

- The Aging Process: Like a good pair of boots, it develops a “patina” over time. Gets darker and softer with sun and oil.

- The Look: No two patches are exactly identical because no two cows are identical.

- Best For: Unique character and premium, rugged branding.

Faux / Vegan Leather

This is a synthetic polymer designed to mimic animal hide.

- The Consistency: If you order 1,000 patches, every single one will be the exact same shade of brown.

- Maintenance: It handles water better than real leather and is easier to clean.

- Best For: Uniformity and fading resistance.

The “Hat Patch” Standard (Richardson 112s)

In Texas, the Richardson 112 trucker hat is the gold standard. We engineer our leather patches specifically for custom hat patches..

The Crown

The 112 has a stiff, structured front. We use a leather thickness that is rigid enough to hold the logo but flexible enough to curve around the forehead without lifting at the corners.

The Bond

We use a high-temp industrial adhesive meant for polyester mesh and cotton blends, ensuring the patch doesn’t peel off in the summer heat.

Texas Heritage & Western Branding

San Antonio is the intersection of Western heritage and modern industry. Leather patches are the default choice for specific industries where character and durability matter.

Ranch & Rodeo

It fits the aesthetic of saddle leather and denim. Perfect for livestock brands, equestrian centers, and western wear.

Oil & Gas Workwear

Leather is tough. It resists abrasion better than embroidery in rough environments like rigs, refineries, and workshops.

Construction

A leather patch on a Carhartt jacket signals durability. It represents the quality of the build and the strength of the crew.

What Is The Difference? (Leather vs. Fabric)

Leather Patches

Leather is about simplicity and texture.

- We aren’t using ink or thread colors to make the logo; we are using depth and burn marks.

- It works best for bold, dark logos.

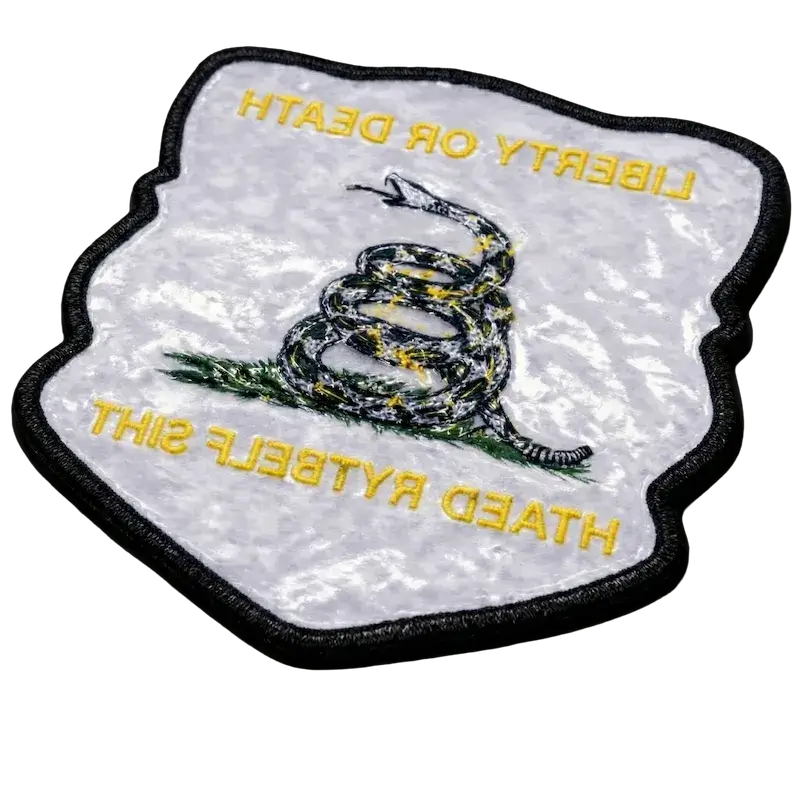

Fabric Patches (Woven/Embroidered)

Fabric is about color and detail.

- If your logo requires bright neons, gradients, or photo-realistic details, stick to Woven Patches.

- You can’t laser engrave a blue sky onto a brown piece of leather.

Backing & Attachment Options

How we attach the leather to your gear changes based on the material.

Heat Seal (Hat Press)

Best for: Trucker Hats (Richardson 112)We apply a thermal adhesive to the back. Using a specialized hat press (which curves to the shape of the cap), we fuse the patch to the fabric at 320°F.

Sew-On (The Stitch Channel)

Best for: Heavy Jackets, Beanies, BagsWe laser-cut a “simulated stitch line” or a groove around the edge of the patch. This gives your sewing needle a track to follow, ensuring a clean, straight stitch application.

Velcro® (Hook & Loop)

Best for: Tactical Vests, Morale PatchesYes, we can put Velcro on leather. We sew the hook backing directly to the leather. This is popular for tactical teams wanting a more subdued, premium look.

Finishes & Effects

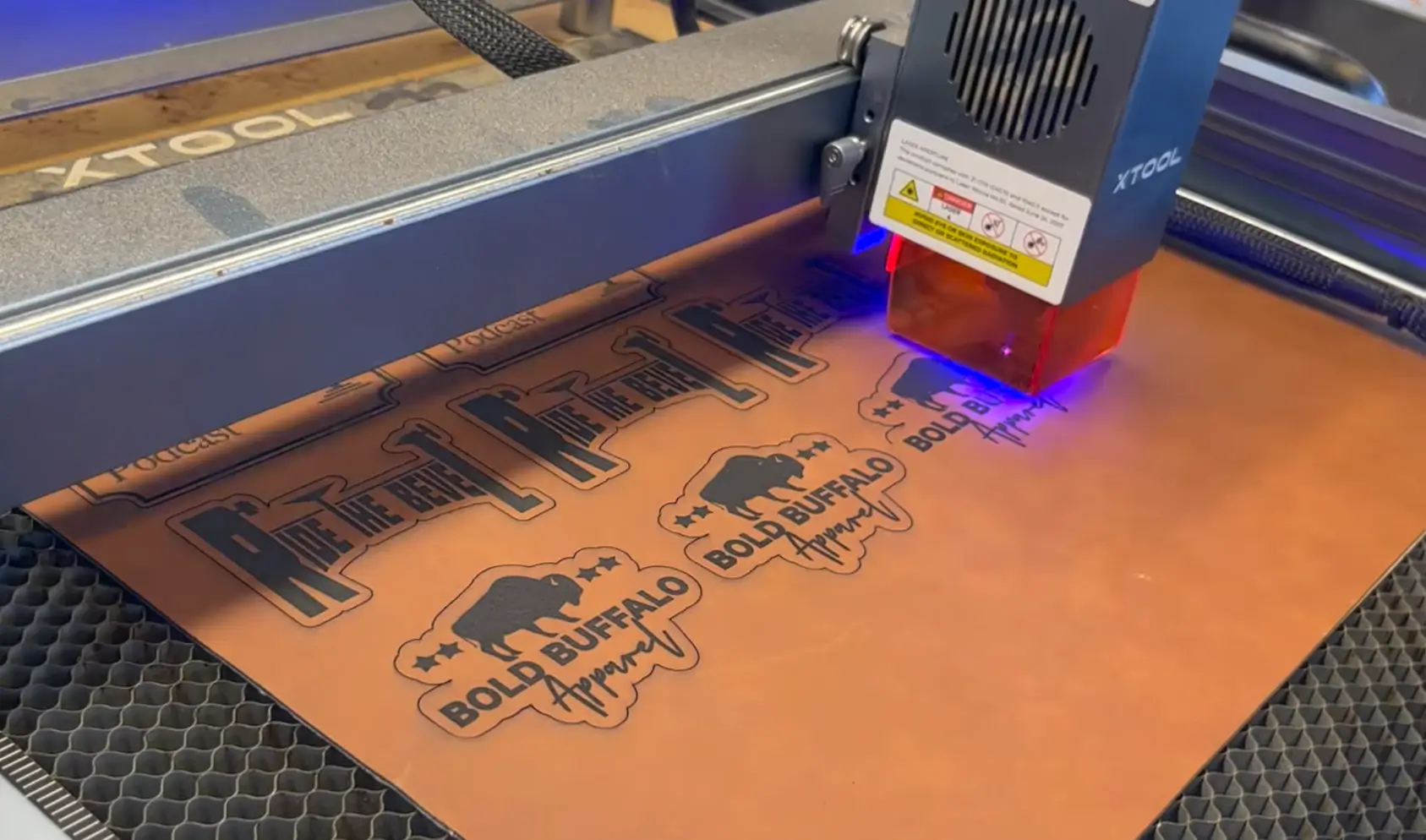

The Burn

The BurnLaser Engraving

We use a laser beam to vaporize the top layer of the leather. This creates a dark, recessed contrast. It’s the most popular method for detailed logos.

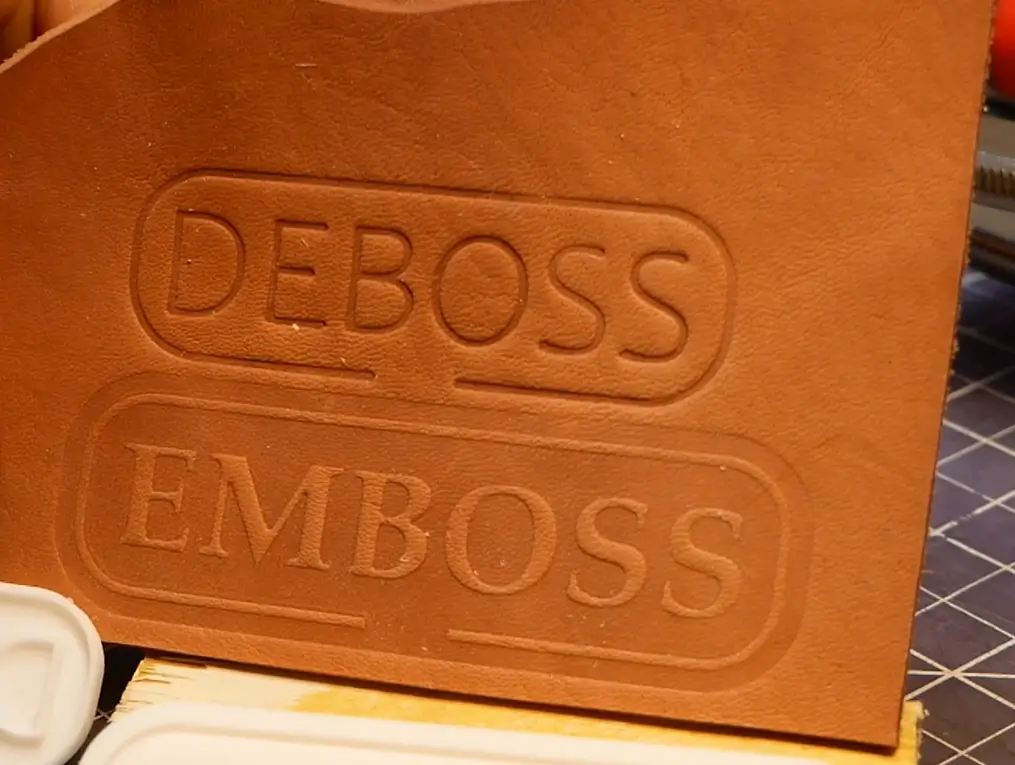

The Stamp

The StampDebossing

We make a metal mold of your logo and use heat and pressure to stamp it into the leather. This creates a 3D “sunken” effect without burning the material.

The Washing Rule

Do not throw genuine leather patches in the washing machine.

Real leather is skin. If you soak it in hot water and detergent, it will dry out, shrink, and curl up like a potato chip.

If you must wash the garment: Hand wash cold and avoid soaking the leather directly.

Choose Faux Leather. It handles the wash cycle much better (though we still recommend air drying to protect the adhesive bond).

How We Price Your Leather Patches

We keep the math simple. There are no “mystery fees.” Here is exactly what affects your quote:

Material

Genuine Leather costs more than Faux Leather. It’s a raw natural material, so the base cost is higher.

Size

We calculate based on the standard formula:

(Length + Width) / 2

A 3-inch patch uses less hide than a 5-inch patch.

Method

- Laser Etching: No setup fees. We just program the laser and burn.

- Debossing (Heat Stamp): Requires a one-time metal mold fee to create the stamp for your logo.

Production & Turnaround

We don’t rush quality, but we don’t waste time either.

Proofing

You’ll get a digital mock-up showing the leather color and stitch line within 24 hours. We don’t cut until you approve.

Production

Once approved, standard production takes 10–14 business days. This includes cutting, engraving, and finishing.

Shipping

We ship nationwide via UPS/FedEx. Tracking is provided as soon as your order leaves our facility.

Leather vs. Other Patch Types | Which One Do You Need?

Leather isn’t for everyone. Here is how to decide if it fits your project.

Choose Leather If:

- You are branding hats Leather is the undisputed king of trucker caps (Richardson 112). It looks retail-ready immediately.

- You want a “Heritage” look If your brand is about outdoors, construction, BBQ, or ranching, leather fits the vibe perfectly.

- Your logo is simple Bold lines and simple text look amazing when burned into leather.

Choose Fabric (Woven) If:

- Color matters Leather is brown (or black/grey). If your logo must be bright red and blue, go with a fabric patch.

- High detail is required We can’t laser engrave a photograph onto leather clearly. For that, you need Woven or PVC.

- Uniform regulations Most official military and police uniforms require specific embroidered patches, not leather.

Why San Antonio Patch Co.?

We are a factory-direct operation. That means when you call us, you aren’t talking to a call center overseas; you’re talking to people who know the difference between a Merrowed edge and a Laser Cut edge.

Direct

Hand-Checked Quality

Leather is unforgiving. If a laser burns too deep, it ruins the patch. We inspect the edges for charring and the stitching for straightness before anything goes in the box.

Local Focus & Fast Support

We know that a patch on an oil rig worker’s jacket in South Texas needs to hold up differently than a patch on a tech startup’s hoodie. We build for our environment.

Straightforward Pricing

No “art fees.” No “digitizing fees” for standard laser files. Just the price of the patch.

The Ordering Process

Send Your Art Work

Vector files (.AI or .EPS) are best for lasers. If you have a JPEG, we can usually make it work. Tell us: Real or Faux?

Approve the Proof

We send a digital proof. You confirm the size and the cut line.

Production

We cut the hides, burn/deboss the logo, and apply the backing.

Get Your Custom Leather Patch Quote

Upload your artwork and receive your free digital proof. Your logo deserves a stitch-perfect finish.

- Free digitizing

- Free shipping

- 100% quality guarantee

Frequently Asked Questions

Common questions about ordering leather patches.

DurabilityAre leather patches durable?

Are leather patches durable?

Yes. Genuine leather is incredibly tough—it’s skin, after all. It resists tearing and abrasion. Faux leather is also durable but won’t last as many decades as well-cared-for real leather.

DesignCan you laser engrave my logo?

Can you laser engrave my logo?

As long as it’s not overly complex. Lasers work in “Black and White”—they either burn the leather or they don’t. We can’t do “grey” gradients. Simple, bold lines work best.

OrdersWhat is the minimum order quantity?

What is the minimum order quantity?

We start at 10 units. If you just need one for a prototype, be prepared to pay a premium for the “sample” setup time.

HeatWill the patch peel off in the summer heat?

Will the patch peel off in the summer heat?

No. We use industrial heat-seal adhesive that activates at 320°F. The inside of a hot truck in San Antonio isn’t nearly hot enough to loosen the bond.

IdentificationHow do I tell if it’s Real or Faux leather?

How do I tell if it’s Real or Faux leather?

Look at the back. Genuine leather has a rough, fibrous suede backing. Faux leather typically has a smooth or woven fabric backing.

MaterialsWhat types of leather do you use?

What types of leather do you use?

We stock a variety of shades: Natural (light tan), Cognac (medium brown), Dark Brown, and Black.

HatsCan I order leather patches for hats?

Can I order leather patches for hats?

Yes. That is 90% of what we make leather patches for. We recommend the “Heat Seal” backing specifically designed for hat presses.

CareCan I put my leather patch hat in the washer?

Can I put my leather patch hat in the washer?

No. Leather is skin. Hot water and detergent will strip the oils, causing the patch to shrink, curl, and ruin the hat’s structure. Spot clean only.

DetailMy logo has tiny text. Will it be readable?

My logo has tiny text. Will it be readable?

Not if it’s smaller than 0.2 inches. Lasers burn material; they don’t print pixels. If text is too small, the burn marks bleed together. We recommend simplifying the design.