Backing Options for Custom Patches

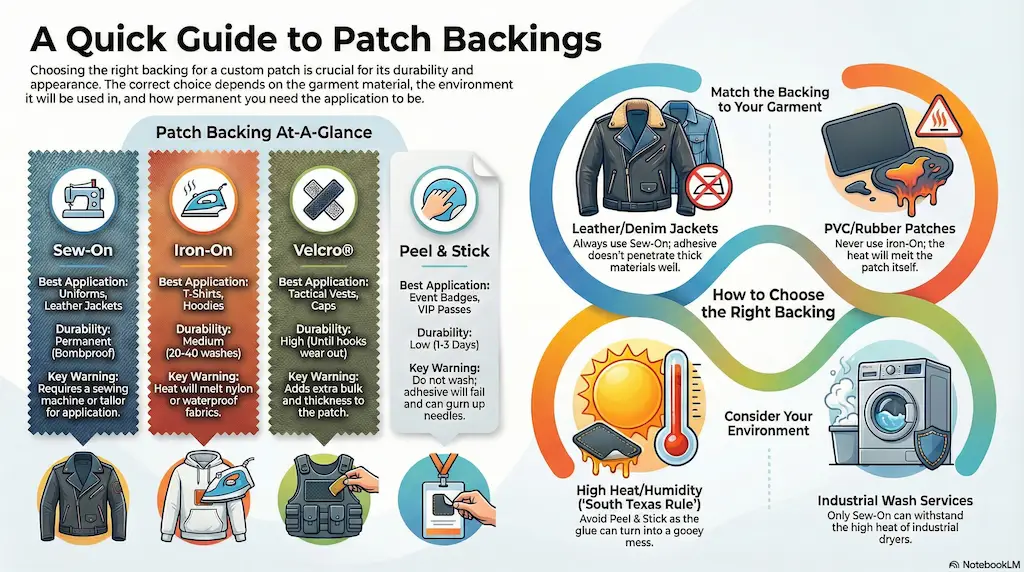

How to choose the right attachment method for your patch durability, comfort, and long-term performance explained simply.How do I choose the right patch backing? The best backing depends on your garment and environment. Sew-on is the only permanent choice for industrial use. Iron-on is ideal for cotton caps and t-shirts. Velcro® is the standard for military OCP uniforms, while Adhesive (Peel & Stick) should be reserved for temporary one-day events. Avoid ironing patches onto nylon or waterproof fabrics to prevent melting.

Quick Summary

Need a quick answer? Here is the 30-second breakdown from our San Antonio production line:

- For Permanence: Choose Sew-On. It is the only industrial-grade option for workwear and leather.

- For Speed: Choose Iron-On (Heat Seal). 15 seconds with a heat press and it’s fused. (Note: Avoid for Nylon/Waterproof fabrics).

- For Military/Tactical: Choose Velcro® (Hook & Loop). Essential for swapping OCP unit patches and morale gear.

- For 1-Day Events: Choose Peel & Stick. Great for temporary branding, but will not survive a laundry cycle.

- For Trucker Hats: Choose Heat Seal. Specially formulated to bond to a cap’s stiff buckram crown.

What Is a Patch Backing?

It stiffens the patch so the embroidery doesn’t bunch up or distort.

It provides the mechanism (glue, plastic, or hooks) to stick the patch to the garment.

Without a proper backing, an embroidered patch is just a limp piece of cloth that will fray immediately.

The Most Common Patch Backing Types

Quick Reference: Patch Backing Compatibility & Durability. The team at San Antonio Patch Co. uses this chart on the factory floor to stop customers from making expensive mistakes.

| Backing Type | Best Application | Durability | Washability | Production Warning |

|---|---|---|---|---|

| Sew-On | Uniforms, Leather Jackets, Heavy Bags | Bombproof (Years) | Industrial Wash Safe | Requires a sewing machine or tailor. |

| Iron-On | T-Shirts, Hoodies, Cotton Blends | Medium (20-40 washes) | Cold Wash / Hang Dry | DO NOT use on Nylon or Waterproof gear. It will melt the fabric. |

| Velcro® | Tactical Vests, Operator Caps, Military | High (Until hooks wear out) | Remove Before Washing | Adds bulk/thickness to the patch. |

| Peel & Stick | Event Badges, VIP Passes | Low (1-3 Days) | Do Not Wash | Gumming up needle? Do not try to sew through this later. |

| Pins/Magnet | Blazers, Delicate Fabrics | High (Removable) | Remove Before Washing | Magnets can be heavy; ensure fabric can support the weight. |

Here is the breakdown of what runs through our machines every day.

Sew-On Backing (The Industry Standard)

Iron-On Backing (Heat Seal)

Velcro® Hook & Loop

Adhesive / Peel & Stick Backing

Pin & Specialty Backings

How to Choose the Right Backing for Your Project

Don’t guess. Use this logic flow.

Backing Options by Patch Type

Not every backing works with every material. Here is the compatibility chart we use on the factory floor.

Why: Since both embroidered and woven patches have a thread base, the adhesive absorbs perfectly into the fibers. It’s the most versatile choice for shirts and caps.

Why: You cannot iron on a PVC patch. The heat required to melt the glue (300°F+) will melt the rubber patch first. We usually sew a hook backing onto PVC for tactical gear.

Why: 90% of leather patches go on hats. We use a specialized industrial adhesive designed to bond leather to the stiff buckram of a trucker hat.

Why: Chenille is thick and heavy (think letterman jackets). Iron-on glue often struggles to penetrate through the thick felt and yarn to get a grip on the jacket. Stitching is the only safe bet.

Backing & Washability Guide

How you clean your gear determines which backing you need.

You can boil it, bleach it, and industrial wash it. The patch will survive as long as the shirt does.

Wash in cold water. Hang dry only. The high heat of a tumble dryer can reactivate the glue, causing the patch to lift at the corners.

Always take the patch off before washing the garment. The “hook” side will snag on your other clothes, and the water will eventually break down the hook fibers.

It will fall off immediately.

Common Backing Mistakes to Avoid

Rookie Mistake

The “Adhesive Trap”The sticky goo gums up sewing machine needles instantly. If you plan to sew it on eventually, just order Sew-On (Plastic) backing. It’s cleaner and easier to stitch through.

Backing Costs & How They Affect Pricing

Backing affects your unit price because of material and labor costs.

Sew-On (Standard)

It’s the default.

Iron-On / Adhesive

Adds a few cents per patch for the glue sheet.

Velcro®

We have to cut the Velcro material and pay a seamstress to sew it onto the patch.

Pin / Magnet

Hardware is expensive, and it must be applied by hand.

Frequently Asked Questions

Common questions about patch backings, durability, and application.

DurabilityWhich backing lasts the longest?

Which backing lasts the longest?

Sew-On. There is no contest. Glue degrades over years; thread does not.

ModificationCan I change the backing after production?

Can I change the backing after production?

Not really. If you order Iron-On, you can still sew it on. But if you order Velcro, removing it is a messy process that usually ruins the patch.

SpecsDoes backing affect patch thickness?

Does backing affect patch thickness?

Yes. Velcro adds significant bulk (about 0.25 inches). Iron-on keeps the patch relatively flat.

StrengthIs iron-on as strong as sewing?

Is iron-on as strong as sewing?

No. It is a strong bond for casual wear, but for a uniform worn daily by a mechanic or a soldier, sewing is required.

ModificationCan Velcro be added later?

Can Velcro be added later?

Yes. You can buy sticky-back Velcro strips at a hardware store, but they rarely hold up. If you want Velcro, let us sew it on at the factory for a permanent bond.

Need Help Choosing the Right Backing?

If you’re still not sure if your gear can handle an iron-on patch, ask us. We’ll tell you straight so you don’t ruin your uniforms.

Get a Quote